Home >News

By the end of January 2022, MGM's TPE coating machine arrived as scheduled at Xianghe Zhongbang. On the last day before the Chinese New Year, the installation and debugging of the new TPE section were completed on the existing MGM IG line onsite. The future of TPE is promising, and Xianghe Zhongbang is advancing with the trend.

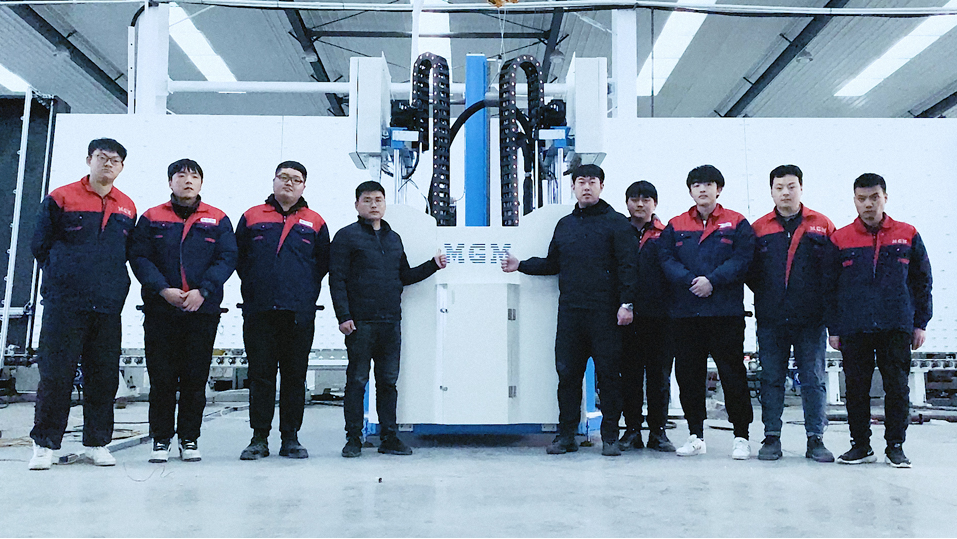

Commissioning technicians and the TPE equipment

MGM's TPE equipment replaces traditional processes such as aluminum spacer bending, butyl coating, and frame assembly. TPE seamlessly integrates with silicone or polysulfide, reducing the heat transfer of insulated glass and enhancing energy efficiency and environmental friendliness. It has already been adopted by numerous large glass manufacturers, including Yinjian, Hengli Dongsen, and Zhongchuan, both domestically and internationally.

Xianghe Zhongbang's general manager Mr. Du (right) and the leader of the installation team (left)

The introduction of MGM's TPE equipment at Xianghe Zhongbang is akin to adding wings to a tiger, promising a leap forward in the development and popularization of TPE. It is believed that TPE will unlock infinite potential for the future growth of Xianghe Zhongbang.

A close-up view of the TPE equipment