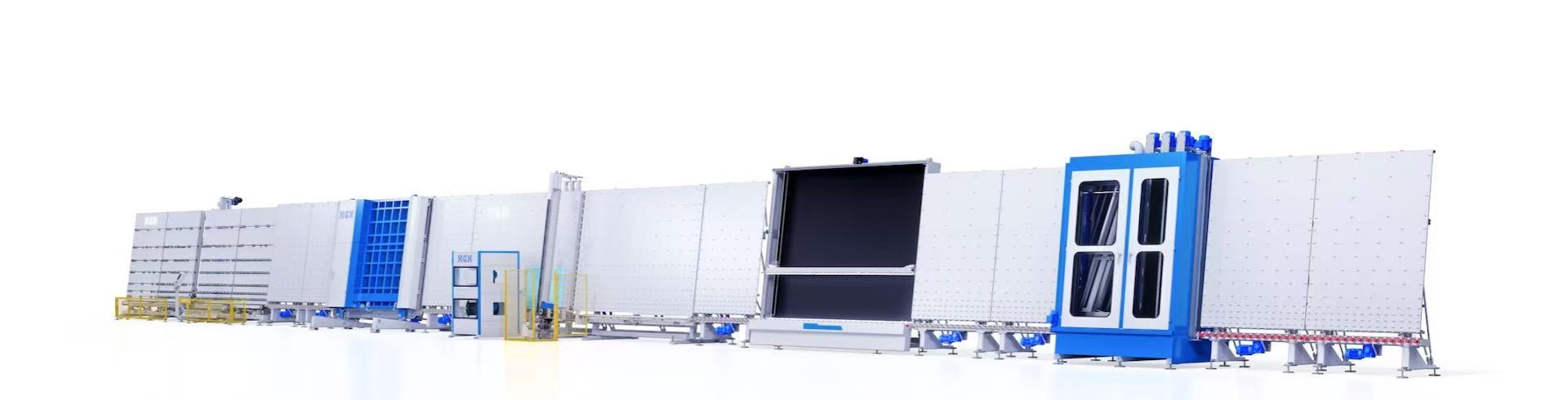

Home >Insulating Glass Lines

| Technical Data | ||||

| Min Size | 160*310mm | |||

| Glass Thickness | 3-18mm | |||

| Spacer Width | 6-19mm | |||

| IG Thickness | <56mm | |||

| Washing Speed | 1-10m/min | |||

| Transport Speed | 1-50m/min | |||

| Transport Height | 550-650mm | |||

| Power Supply | ≈85kW | |||

| IG Types | Double glazing, Triple glazing, Shapes | |||

| Options | In-panel gas filling | |||

| Max Size | 1800X3600mm | 2700*3500mm | ||

✔ High glass washing quality: fast cleaning speed, low noise, sand and carbon filters with soft coated LOWE brushes and air knives ensuring a water-free glass surface with no scratches

✔ Inspection and spacer placement station featuring a specially treated coating to reduce glare and enable comprehensive inspection

✔ Super flexible spacer applicator: precision placement of super flexible spacers at high speed for maximum output, and allows for inverse corners and variable shapes

✔ Gas filling pressing: rapid argon gas filling over 90% efficiency, precise lamination, servo-controlled, and high pressure accuracy

✔ Integrated with automatic loading/unloading systems to enable complete production line automation, minimization of manual labour and improving efficiency dramatically

✔ Configurable for both super flexible spacers and conventional aluminium spacers, enabling convenient switches

✔ Spacer storage accommodating two types of spacers for flexible production

✔ Single-piece pressing panel design ensuring even and consistent pressing flatness